LINSHI: Replacement Fuel Injector Seal Kits

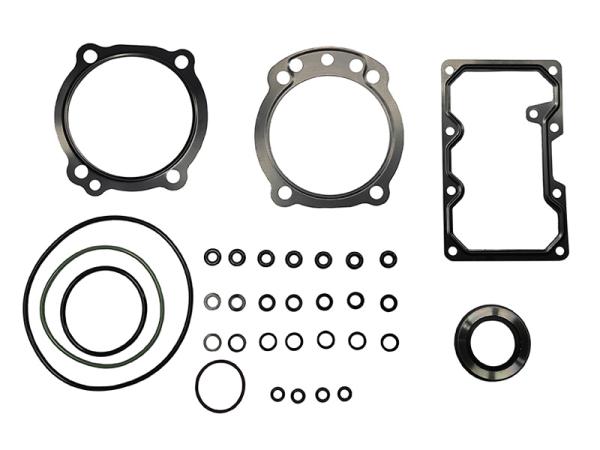

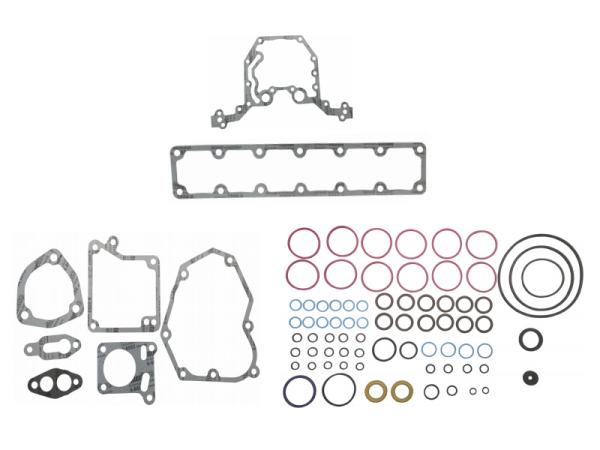

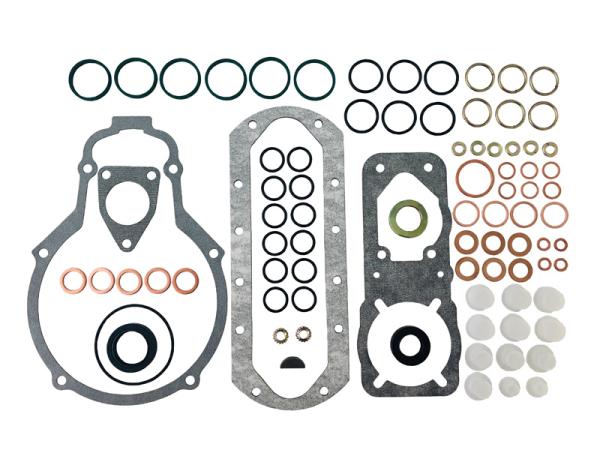

Common Rail Injector Shims, Common Rail Injector Repair Kits, Injector Adjust Gasket, CAT Gasket, Metal Gasket, Adjusting Gasket, CAT Repair Kits, Gasket Kits, Fuel Injector O Ring Kits, Rubber Seal Ring, Seals & O-Rings, Fuel Pump Seal and Repair Kits.

High quality material, a complete range of specifications, can be customized, high strength, precision quality, smooth and bright, uniform force, strict quality inspection, detailed controllin, rest assured to use.

China directly factory, Most competitive price, Fast delivery, Free samples, High quality, OEM different package and size for clients need. Contact with form or Send mail: [email protected]

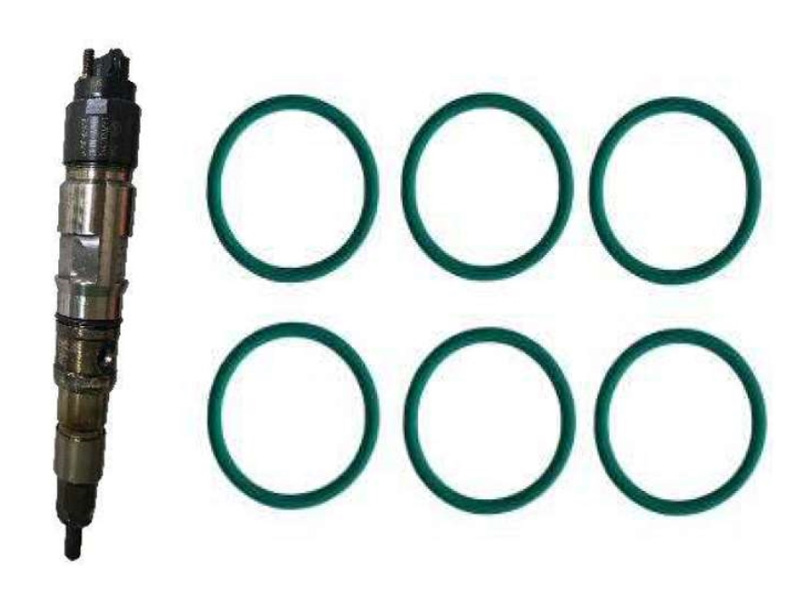

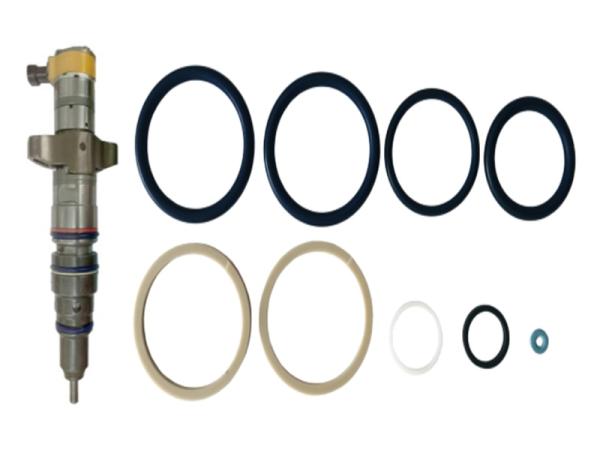

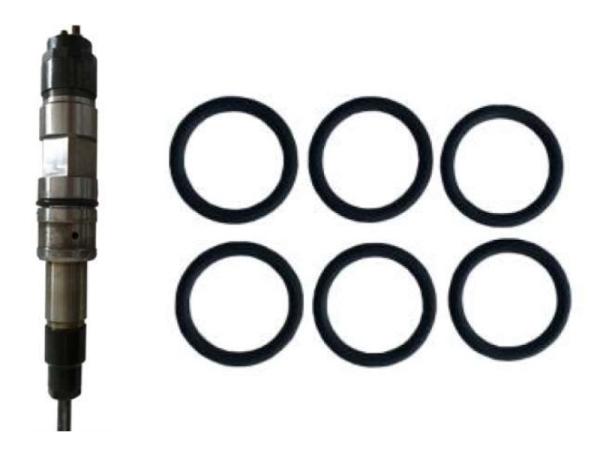

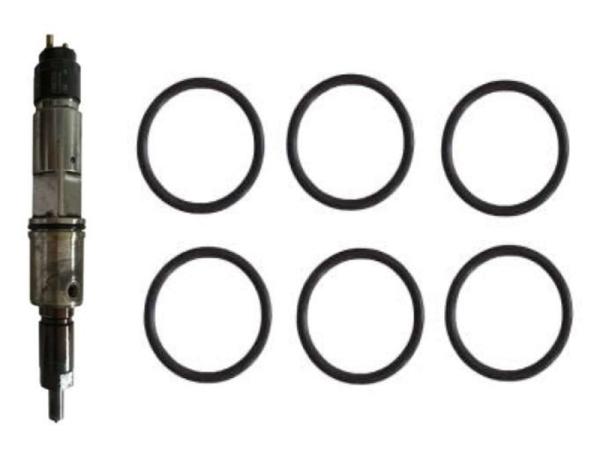

Fuel injector seals, Replacement kits, Injector seal O rings

Fuel injector seals are a critical component in the fuel injection system of internal combustion engines, such as those found in cars, trucks, and other vehicles. Fuel injector seals play a critical role in the performance and efficiency of your car’s engine system. These seals are designed to prevent fuel from leaking out of the fuel injector and into areas where it shouldn’t be, such as the combustion chamber or the engine bay, While ensuring that the fuel is delivered to the combustion chamber without any loss or wastage. They also help maintain the proper pressure within the fuel injector for efficient fuel atomization and combustion.

The fuel injector seal is an elastic sealing element that wraps around the head of the fuel injector and fits tightly with the tapered head of the fuel injector. Fuel injector seals are small but essential components of your engine system. Injector seals must have the characteristics of high temperature resistance, corrosion resistance, high elasticity, sufficient strength and wear resistance. They are made of high-temperature resistant rubber, metal or silicone and are located between the fuel injector and the cylinder head. Metal seals have high strength and high wear resistance, but are expensive and are mainly used in high-performance engines. Plastic seals have better corrosion resistance and higher elasticity and are suitable for most automotive engines. Rubber seals have better sealing performance and longer service life, and are suitable for engines with higher requirements. During engine operation, the injector seal will be affected by high temperature and high pressure, so it needs to maintain its original performance under high temperature and high pressure environments.

In order to ensure that the injector seal can perform its due function, it is necessary to pay attention to cleanliness, correct installation direction and correct installation pressure during installation. Over time, fuel injector seals can wear out, crack, or harden, losing their sealing ability. This can result in fuel and air leakage, which can cause poor engine performance, increased emissions, and fuel consumption. during engine maintenance, it is necessary to regularly check whether the injector seal is worn or aged, and replace it in time to ensure the normal operation of the engine.

Checking and Replacing Fuel Injector Seals

Checking and replacing fuel injector seals is an essential part of routine vehicle maintenance. To make sure your injector seals are in good condition, you should check them regularly for any damage or wear. This can include cracks, tears, or other visible defects. If you notice any of these issues, it’s important to address them right away, as damaged seals can lead to fuel leaks and other problems.

Learn more about how to checking and replacing fuel injector seals

Common rail injector shims

Common rail injector shims, fuel injector seals is an important component used to adjust and maintain common rail injectors. In the high-pressure fuel system, the common rail injector is one of the key components for injecting fuel. The reliability and accuracy of its operation directly affect the performance and fuel economy of the engine. The common rail injector gasket is an important component used to adjust the injection pressure, fuel injection volume, injection angle and other parameters of the injector.

Common rail injector shims are usually made of high-strength, high-pressure-resistant metal or non-metallic materials, and have certain elasticity and deformation capabilities. During the operation of the injector, the common rail injector gasket can withstand the pressure and impact of high-pressure fuel, while also ensuring the sealing performance of the injector.